Vehicle Resilience Testing

Vehicle Resilience (VRES) brings together the three key disciplines of Cybersecurity, Electromagnetic Resilience and Functional Safety.

This provides an integrated and complementary service to help our customers deliver safe, secure and connected products.

Vehicle Resilience is increasing in importance as achieving public trust means establishing unquestioning reliance on resilient and dependable technology. This requires a combined approach of proactive (preventative) design and reactive (remedial) engineering and solutions. Additionally, this must be supported by strong independent assurance frameworks meeting legal and regulatory requirements.

Here are the main types of tests in each category:

Cybersecurity Testing

- Penetration Testing: Ethical hackers attempt to breach the vehicle’s software and network security to uncover vulnerabilities and weaknesses that could be exploited by cyber attackers

- Vulnerability Scanning: Systematic scanning of vehicle systems and software to identify potential security vulnerabilities, such as software bugs or misconfigurations

- Threat Modelling: Analysing the vehicle’s architecture and identifying potential cyber threats and attack vectors to design appropriate security measures

- Security Code Review: In-depth examination of the source code to identify security flaws and vulnerabilities in the software

- Security Risk Assessment: Evaluating the risk associated with identified vulnerabilities and determining the severity of potential cyberattacks

Functional Safety Testing (ISO 26262)

- Hazard Analysis and Risk Assessment (HARA): Identifying and analysing potential hazards and risks associated with vehicle functions and systems

- Failure Mode and Effects Analysis (FMEA): Evaluating potential failure modes of vehicle components and their effects on safety

- Hardware-in-the-Loop (HiL) Testing: Simulating vehicle systems to verify the functionality of safety-critical components and their interactions

- Software Testing: Ensuring that embedded software functions as intended, is free of critical errors, and meets safety requirements

- Validation and Verification Testing: Confirming that safety-related functions meet their specified requirements and operate correctly

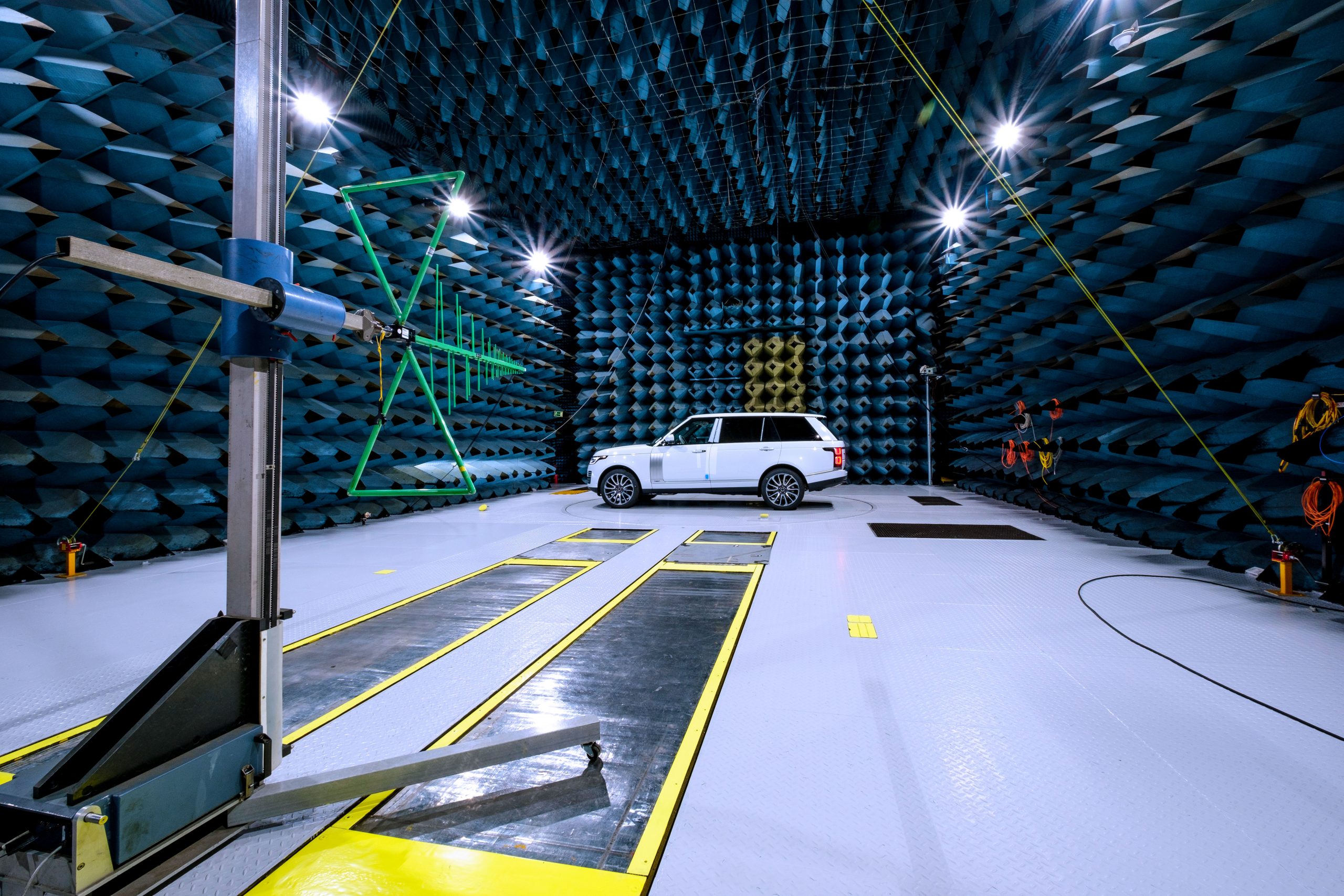

Electromagnetic Resilience Testing

- EMC (Electromagnetic Compatibility) Testing: Evaluating the vehicle’s ability to operate without interference in electromagnetic environments. This includes radiated and conducted emissions testing

- EMI (Electromagnetic Interference) Testing: Assessing the impact of electromagnetic interference on vehicle systems and evaluating their resilience

- Electrostatic Discharge (ESD) Testing: Testing the vehicle’s resistance to electrostatic discharges, which can cause malfunctions

- Immunity Testing: Subjecting vehicle components to electromagnetic interference to ensure they can operate reliably in adverse electromagnetic conditions

- Transients Testing: Evaluating how vehicle systems respond to sudden voltage spikes or drops, which can affect safety-critical functions.

Speak to an Expert

If you would like to discuss your testing requirements with one of our experts, please send us a message and we will contact you as soon as possible.