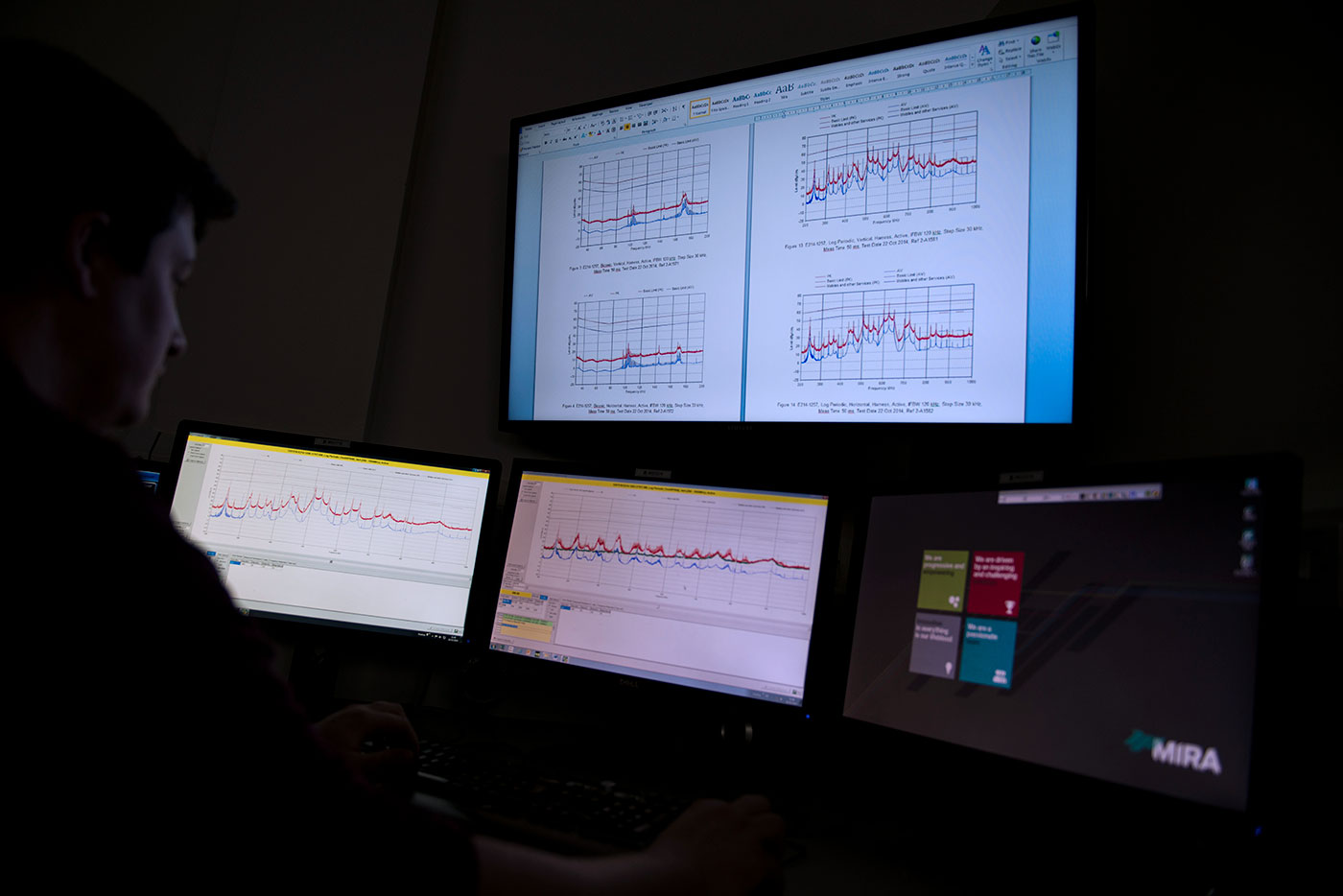

EMC Component Testing Facilities

The Electromagnetic Compatibility (EMC) component and sub-system testing facilities are accredited for all applicable automotive, military & commercial EMC international standards and directives as well as being approved and recognised by all major vehicle manufacturers test schedules.

HORIBA MIRA’s Automotive EMC component testing is complemented by our environmental test service offering customers a single location for automotive component sign-off. Our facilities meet the requirements of the automotive UNECE Regulations, where we are also an EMC Technical Service for the VCA, RDW, NSAI & VSCC

HORIBA MIRA’s expertise and capabilities in EMC encompass RF Immunity & Emissions, Electrical Transients and EMF testing.

All of our facilities have the ability to allow the customer to access the testing ‘live’ allowing them to not only witness the testing without the need for travel but additionally enabling them to flash new software to their component without being present at HORIBA MIRA, ensuring support from anywhere in the world.

Our facilities and capabilities include:

- 24 hours per day operation to reduce dependence on prototype

- 2 ALSE EMC Facilities

- 2 Screened Rooms

- 4 Electrical Facilities

- Electric Vehicle (xEV) & Sub-Component Facility

- Radiated & Conducted Emissions

- Radiated Conducted Immunity

- Electrical Transients

- Electromagnetic Fields

- Fibre optic monitoring for all automotive networks (CAN, LIN etc) pneumatic control of vehicle systems and remote access for diagnostic support from anywhere in the world

- Dedicated alternator and ISG test rig

- Broadcast suite enabling Radio, TV, Cellular and E-Call etc simulations

- Re-radiating GNSS, 3G and 4G networks

- Approved by all major vehicle manufacturers including AML, Ford, GM, Fiat Chrysler, JLR, Stellantis, BMW, Mercedes, Hyundai, Nissan, and VW

This facility has achieved the ISO 17025 accreditation for the competence of testing and calibration laboratories