Large Climatic Vibration Facility

The Large Climatic Vibration Facility at HORIBA MIRA is uniquely equipped to deliver high-acceleration vibration testing for large and heavy components, particularly in the automotive, aerospace, defence, and industrial sectors. The facility is ideal for full-scale testing of high-voltage electric vehicle (EV) batteries, whether it’s a 100+ kWh system for passenger vehicles or a multi-hundred kWh pack for off-highway and construction equipment.

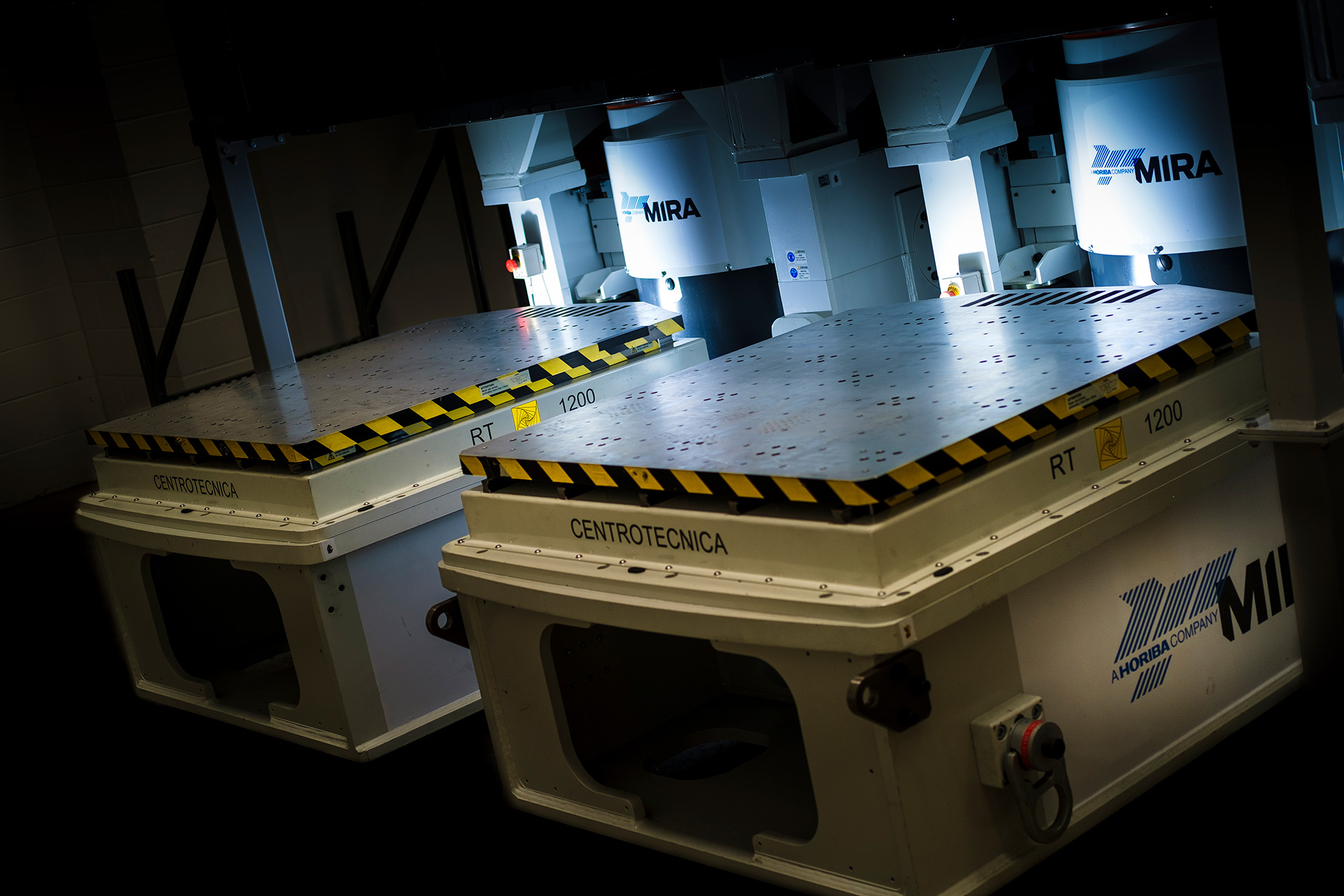

Two High-Performance Shakers for Maximum Flexibility

To meet a broader range of vibration test requirements, the facility now houses two powerful vibration systems:

- The original large climatic vibration shaker, capable of handling several tons of load and providing high excitation forces and electrical and thermal cycling in ambient conditions ranging from -40°C to 100°C.

- The newly commissioned IMV K350, offering the highest level of excitation force and payload capacity currently available in the UK.

NEW: IMV K350 Vibration System – UK Exclusive

We are pleased to introduce the IMV K350 vibration system, the only one of its kind in the UK. This advanced, water-cooled shaker is designed to meet the most demanding vibration test requirements, supporting larger payloads, higher forces, and longer strokes than conventional systems.

K350 Technical Specification

- 300kN sine excitation force and 900kN shock force

- Acceleration up to 1000 m/s² sine and 2000 m/s² shock

- Frequency Range: 0–2000 Hz

- Load Capacity: In excess of 3000 kg

This system is ideal for testing to internationally recognised vibration and shock standards, including:

- UN ECE R100

- UN 38.3

- ISO Standards

The Large Climatic Vibration Laboratory enables battery charging and discharging whilst in use, along with climatic capability, to carry out tests in ambient conditions ranging from -40°C to 100°C.

The twin-vibration facility can operate in three axes and has the capacity to vibrate up to 2.5 tonne of mass, meaning that we can test the biggest EV batteries in the market to regulatory standards such as UN38.3 and UNECE R100.

The test beds can also operate in single mode, allowing two smaller batteries to be tested in parallel.

The ‘shaker’ can be programmed with customer or industry duty cycles (both electrical and thermal) – a unique function that will provide test results representative of real-world conditions.

Why Choose HORIBA MIRA?

- Dual Shaker Setup: Provides unmatched flexibility for both standard and extreme vibration testing scenarios.

- Full-Scale Vibration Testing: Capable of simulating extreme real-world conditions for large components.

- Unrivalled Payload Capacity: The only facility in the UK able to test items up to 3000 kg under severe conditions.

- Advanced Environmental Capability: Part of HORIBA MIRA’s wider environmental test estate, with 19 climatic chambers, ranging from small boxes to walk-in rooms.

- Accelerated Time to Market: Efficient test planning and execution to meet tight development timelines.

- Engineering Expertise: Our team provides support from test definition through to execution, helping clients navigate complex test requirements with confidence.

- Proven Track Record: We are the testing partner to some of the world’s leading automotive manufacturers and aerospace and defence companies.

Supporting Your Testing Needs

Whether you’re validating the structural durability of an electric vehicle battery, aviation component, or defence system, our Large Climatic Vibration Facility enables robust, repeatable and regulation-aligned testing, delivered by a team of experienced test engineers. With two of the most powerful shakers in operation in the industry, we offer greater scheduling flexibility, test throughput and the ability to match each test article with the optimal setup.

This facility has achieved the ISO 17025 accreditation for the competence of testing and calibration laboratories