Vehicle Body, Structure and Attachments Testing

Vehicle body, structure, and attachment testing for automotive vehicles is essential to ensure the structural integrity, durability, and safety of the vehicle’s components.

These tests help manufacturers design vehicles that can withstand various loads and stresses encountered during normal driving and potential accidents.

Here are the main types of testing in this category:

Static Load Testing

- Roof Crush Test: Evaluates the strength of a vehicle’s roof by applying a static force to simulate a rollover event and assesses the roof’s ability to protect occupants.

- Door Slam Test: Assesses the durability and functionality of vehicle doors by repeatedly opening and closing them with force.

- Bonnet and Boot Lid Load Testing: Measures the strength and integrity of the bonnet and boot lids by applying loads to simulate various scenarios, such as hail impact or luggage storage

Dynamic Structural Testing

- Dynamic Bending Test: Subjects the vehicle’s chassis and body to bending forces to assess its structural integrity and resistance to deformation.

- Dynamic Torsion Test: Evaluates the vehicle’s resistance to twisting forces that may occur during cornering or uneven road conditions.

Durability and Fatigue Testing

- Rigorous testing simulates real-world driving conditions, including road vibrations, potholes, and other stressors, to assess how well the vehicle’s structure and attachments hold up over time.

Suspension Attachment Testing

- Suspension and Chassis Component Testing: Evaluates the performance of suspension components, such as control arms, bushings, and subframes, under various loads and road conditions.

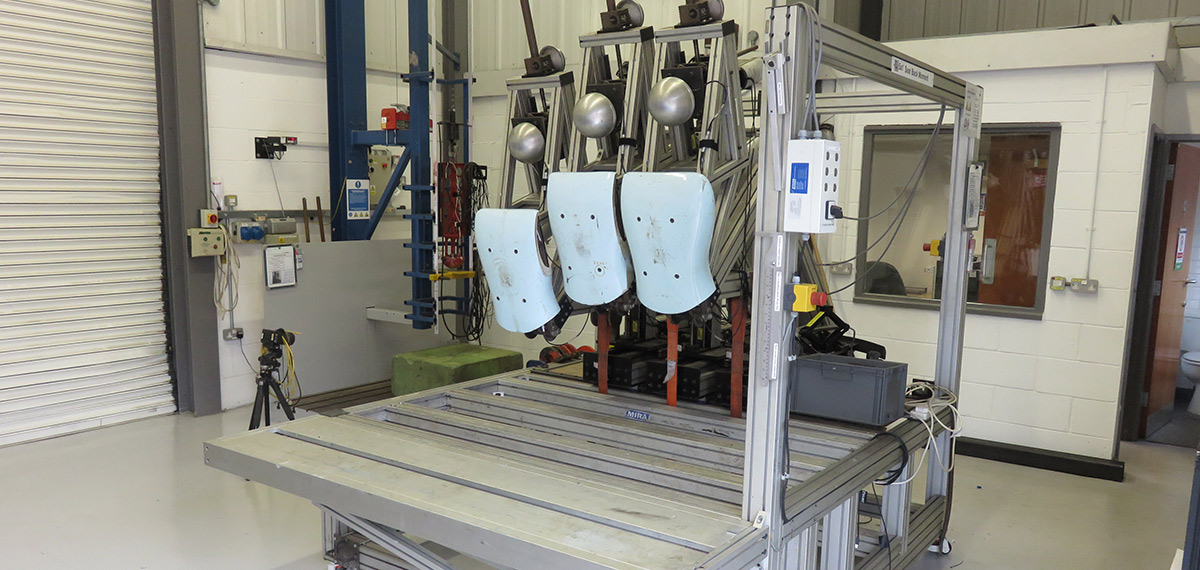

Fasteners and Attachments Testing

- Bolt Torque and Tension Testing: Ensures that bolts and fasteners are tightened to the appropriate torque specifications and maintain proper tension.

- Attachment Point Testing: Assesses the strength and integrity of attachment points for components like seats, seat belts, airbags, and child restraint systems.

Corrosion Resistance Testing

- Exposes vehicle components and structures to harsh environmental conditions, such as salt spray or humidity, to evaluate their resistance to corrosion and rust.

Vibration and Harshness Testing

- Measures how the vehicle’s body and attachments respond to vibrations and impacts during driving, ensuring they do not compromise comfort, functionality, or safety.

Cradle and Chassis Testing

- Evaluates the strength and durability of the vehicle’s chassis, frame, and undercarriage components to withstand impacts, road irregularities, and stressors.

Crashworthiness Testing

- Ensures that the vehicle’s body and attachments provide optimal protection to occupants during crashes, absorbing and dissipating energy to minimise injuries.

Acoustic and NVH Testing

- Assesses how the vehicle’s body and attachments contribute to noise, vibration, and harshness levels, helping engineers optimise acoustic comfort.

Speak to an Expert

If you would like to discuss your testing requirements with one of our experts, please send us a message and we will contact you as soon as possible.